The Parkz Update: Sea World, May 2013

Sea World's Storm Coaster is slowly starting to shape up. In this edition of the Parkz Update we take a look at the construction site that is starting to reveal a ride layout, and the car park that is filled with all sorts of twisted steel.

Storm Coaster

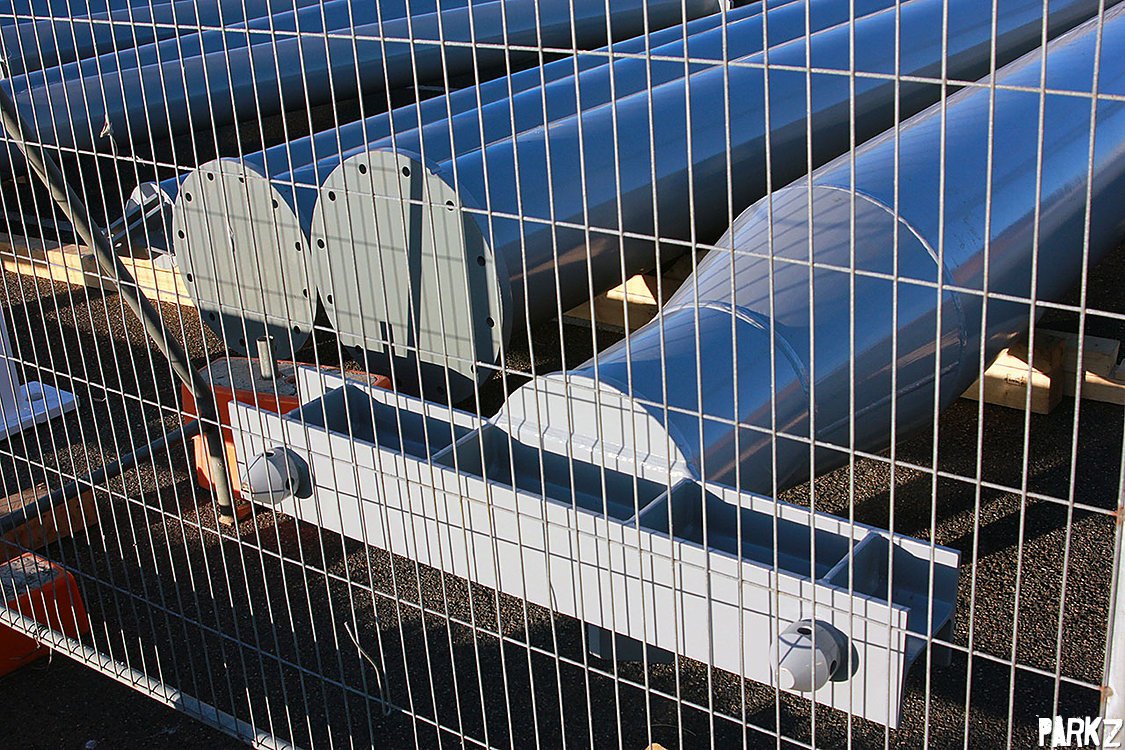

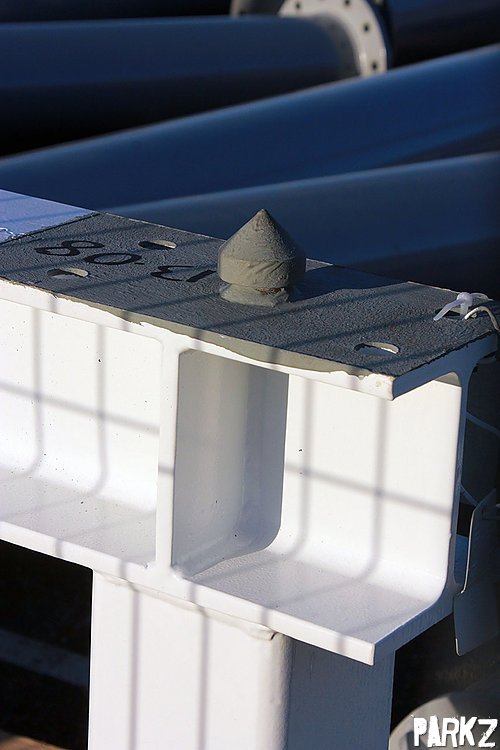

Track in the car park...

Sea World's car park is slowly filling with mountains of steel track and supports.

That's it for another Parkz Update! As you can tell there's going to be all sorts of exciting things happening at Sea World in coming months – as always stay tuned to Parkz for the latest!

Featured in this article

Recent articles

Now trending